A Klaveness Combination Carrier departs from New York, heading for the Bahamas. While the ship is in transit at sea, an advanced robotic system is at work inside one of its cargo tanks.

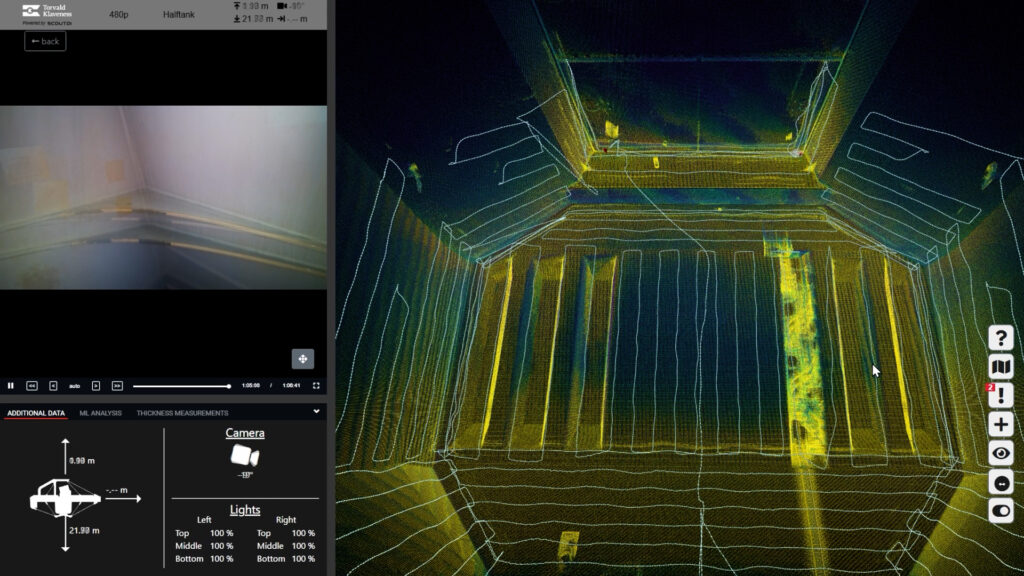

Deep within the steel confines of the vessel, the Scout 137 Drone System carries out a fully automated cargo tank inspection, executing an inspection plan, capturing data, and mapping the tank’s interior without any manual piloting.

This is the future of cargo tank inspections, and the results of the test were promising.

Why Automation Matters in Cargo Tank Inspections

Thorough cleaning between cargos is critical both for dry bulk carriers, product tankers, chemical vessels and combination carriers, as is the inspection that follows.

The Scout 137 Drone System can be used to verify the cleaning and ensure that one cargo does not contaminate the other.

In other cases, Cargo tank inspections are critical for ensuring vessels coating system, cleanliness, integrity, safety, and regulatory (statutory and class) compliance.

Traditionally, these inspections require human inspectors to enter confined spaces, climb scaffolding, or operate lifts—a process that is not only time-consuming but inherently dangerous.

With Scout 137’s automated inspection capabilities, these challenges are being replaced with a safer, faster, and fully repeatable approach:

✅ Avoid human entry into confined or hazardous spaces

✅ No scaffolding or work at heights

✅ Consistent, repeatable data collection for historical comparisons

✅ Real-time 3D mapping and visual inspection data

✅ Crew involvement limited to equipment setup, requiring less training and logistics.

Adding to the equation the unlimited flight time enabled by the Scout 137’s tether system, restrictions on inspection time are removed. This allows automatic inspection of vast volumes in one go, without human interaction and resulting in a single dataset for the entire job.

This inspection was completed in about an hour, from take-off to landing, minimizing downtime and ensuring the vessel was ready for its next operation without delay. The implications are massive, not just in terms of efficiency, but also in reducing logistical overhead.

The Power of Repeatable, Data-Driven Inspections

One of the biggest advantages of a system that can be automated like Scout 137 is that once an inspection path is created, it can be reused indefinitely. This introduces a new era for confined-space inspections where:

- Inspections are no longer a “one-off” event, but rather part of a continuous data collection process.

- Operators can return to the same Points of Interest (POIs) every time, making it easier to track structural changes over time.

- Maintenance teams gain data consistency, reducing uncertainty in corrosion tracking, coating breakdown, deformation analysis, and defect identification.

This shift from manual piloting to repeatable automation fundamentally changes how vessels are inspected. Operators won’t have to re-fly the same asset manually—they can simply re-run a proven, optimized flight plan and focus on analyzing the data instead of collecting it.

From Automation to Full Autonomy

At this stage, the Scout 137 Drone System follows pre-planned inspection paths, which can be created using a 3D CAD-like tool. This allows operators to:

- Define flight paths and pre-set POIs for image capture.

- Ensure the drone follows a safe and optimized trajectory.

However, the long-term vision for autonomous inspections extends far beyond this. For example, how about:

- Fully self-directed inspections—where the drone can enter a space, explore, map its environment, and identify areas of interest without human input.

- AI-driven decision-making—where the drone identifies structural anomalies on its own, prioritizing inspection points based on machine learning.

- Automated UT (Ultrasonic Thickness) measurements—where the drone not only captures visual data but also performs direct thickness measurements at predefined POM (Points of Measurement).

A Step Closer to the Future of Inspection

This automated cargo tank inspection is not just a demonstration of technology, it’s a glimpse into the future of how industrial assets will be monitored, maintained, and managed.

As automation in confined-space inspections progress on the path to autonomy and becomes more advanced, operators will be able to rely on past inspections as reusable templates, ensuring consistent, more frequent, high-quality data capture with minimal manual intervention.

And the best part? We’ve defined the steps to achieve this goal and are working on the implementation. The Scout 137 Drone System is prepared for redefining what’s possible in confined-space inspections.

PS: The Bahamas were great.

Got an idea or a question? Let’s discuss your application of the Scout 137 Drone System.

Contact us to learn more👍